CSA Aircrete Formula – 3rd Test Batch

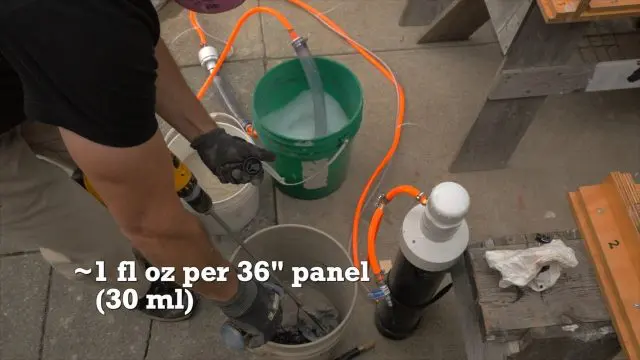

In the third mix I upped the cement ratio. It’s now 20 lbs of Cement All, 4 lbs of water, about the same amount of foam, 2 teaspoons of plasticizer, and a bit of fiber.

And I’ll add charcoal liquid colour to the water this time.

Once well blended I add the foam and mix that in well.

And then pour it into the form. Shaking it to settle the CSA aircrete. After it begins to thicken I added the wire grid. I pressed this in and smooth with a trowel.

When the CSA aircrete began to warm, and the surface dried with a white haze, I sprinkled water over it. I repeated this for an hour. Keeping the surface wet as it cured. I covered them with plastic and left them overnight.

Water Curing

Stripping the Forms

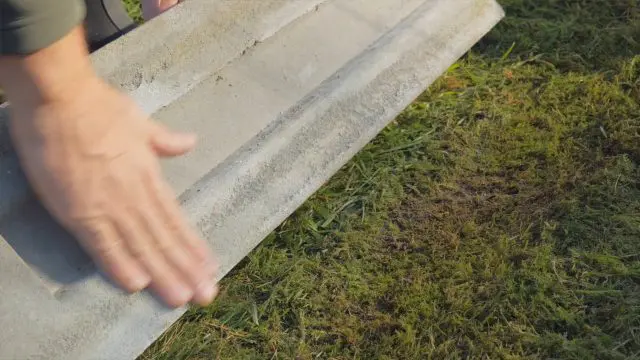

The next morning I stripped the forms from the castings. I remove all the screws from the form, gently wiggle the sides to free them, then remove the panel from the base and stand it on one side. And then remove the ends.

The sand in the Cement All was noticeable in these panels compared to Portland-based aircrete. And I had hoped that it would make the panels more durable and impact resistant.

All the panels came out of the forms well. They all felt sound and solid. Other than some surface blemishes around the panel inset, there were no significant cracks or any signs of warping.

Longer Water Curing

As in my last two videos, these panels where also submerged in water in an improvised tank. They soaked for two weeks then were pulled out and left to slowly dry in my shop for another two weeks.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

Surface Durability Test with Line Trimmer

I then weighed the panels and lined them up on the lawn and ran a line trimmer along them all. As a test for surface durability. The first two panels didn’t do so well. The line trimmer cut grooves in the surface.

The third panel, with a higher percentage of Cement All did better. It only had minor damage.

Weight Reduction Results

The first two panels were very close in weight and averaged 64% lighter than regular gravel and sand based portland concrete.

The third panel was 52% lighter than regular concrete. I used more Cement All in this one cause I just had a hunch that this type of aircrete needed to be denser.

The panels look good and the bubbles appear to be uniform. I didn’t see any cracks forming or any warping as they fully cured and dried. So the density of the cement seems to be adequate so the panel can resist the internal stresses that build up during curing and drying.

I had hoped that the stronger CSA cement would make these panels more durable but they didn’t do so well against the line trimmer. The denser third one did better than the first two.

Final Thoughts on CSA Aircrete

So I hope that was helpful. And I think it showed that aircrete can be made from CSA based cement.

I can’t say just yet that it’s any better than a portland based version. There’s a possibility that the sand is actually detrimental and weakens the tiny bubbles. I’d have to get my hands on some pure CSA cement to see if that was the case.

Thanks for reading!

And, while you are here, please hit the Support Link to help us make more projects and videos like this. We really appreciate anything you can do to help us out!