Make your own CSA aircrete lightweight concrete raised garden beds! This is PART 3.7, showing options to make your garden boxes from CSA Air Crete. You can build these forms and cast your own 48″, 36″, or 24″ reinforced lightweight concrete panels that link together to make long lasting and durable concrete garden boxes. #aircrete

Here is the weight of 3 cured panels made from regular concrete: . 48″ – 69lbs, 36″ – 50lbs, 24″ – 33lbs.

See the Youtube Video and download the Plans.

Background for the Cast CSA AIrcrete Garden Box Project – PART 3.7 #aircrete

Hi, its Kent from MAN about TOOLS and this is yet another follow up to Part 3 of my series on making garden box panels from lightweight concrete. And this time I’ll make aircrete using CSA cement.

This is part 3.7 of my series on casting your own reinforced concrete garden box panels. As you may have seen, these panels link together to make rot proof long lasting garden boxes.

In Part 3.6 I reworked my aircrete blend and the results were really good. Many viewers wanted to know if you could make aircrete from CSA cement. So this video is about doing just that.

If you haven’t seen part 1 and 2 of this series then you might get more from this video if you watch them first as I won’t be covering all the steps needed to make the forms and prep them for casting. See the link in the upper right or in the description below.

I’ll be using the plywood forms I built in part 1 of the series. These forms have a durable and smooth polyurethane coating that seems to work well with aircrete.

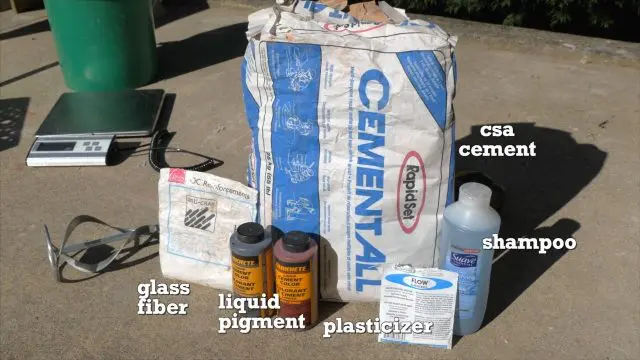

CSA Aircrete Ingredients

Okay, here’s how I made the panels.

The CSA aircrete is made from only a few ingredients: CSA cement, shampoo to create a foam, a little glass fiber for extra strength, and a plasticizer to liquefy the mix. I’ll also add some liquid colour too.

CSA Aircrete Foam Dilution

I’ve covered the shampoo dilution steps in other videos so I’ll just do a quick summary here.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

It’s 15 fluid ounces of shampoo to two and a half gallons of water. I stir this with a paint mixer, on a low setting, to dissolve the shampoo in the water. Then I store the dilution in jugs for later use. This Suave Daily Clarifying Shampoo works really well for aircrete.

Honeydo Carpenter’s Foam Mate

To make the foam I’ll be using the large Foam Mate that Darwin from The Honeydo Carpenter sent me. I pour the shampoo dilution in the tank, connect my air hose, and it makes awesome foam.

Link to Darwin’s channel and his Foam Mate .

I don’t have pure CSA cement so I’ll use a product called Cement All. It has CSA cement mixed with fine sand.

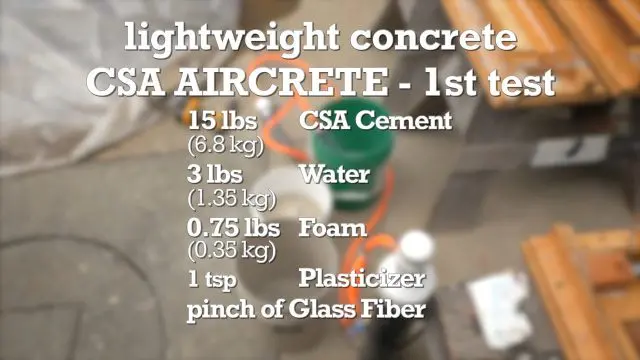

CSA Aircrete Formula – 1st Test Batch

I use a digital scale to weigh my ingredients. I use 15 pounds of Cement All, 3 pounds of water, 3/4 of a pound of foam, 1 teaspoon of plasticizer, and a pinch of fiber.

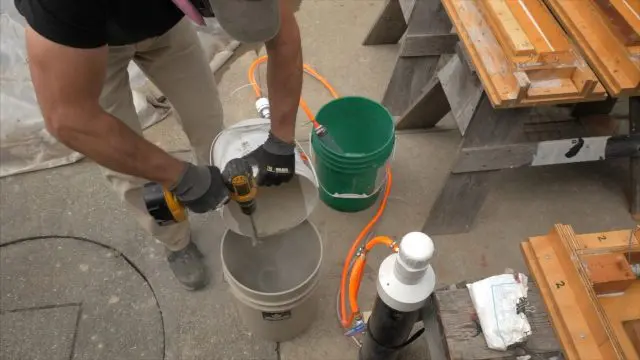

I start by adding a teaspoon of the plasticizer to the water.

Then slowly add the Cement All to the water while spinning the slurry with a paint mixing attachment on a drill.

I don’t want any clumps or dry cement on the bottom or sides of the pail. I use a dowel to hand stir the mix to prevent this.

I’ll add the glass fibre and mix that in.

Now the slurry is ready for foam. I connect my air hose to the Foam Mate and once it’s flowing well and becomes thick I add some to the slurry pail. I have a mark on my stir stick that approximates the amount of CSA aircrete I need to fill one 36″ form. For a five gallon pail, I need it filled to the 8″ mark as a minimum.

I think on this first batch I added a little too much foam. But I decided to go ahead with it anyways knowing that the density of this first panel would be lighter.

Pouring CSA Foamcrete into Forms

I pour the CSA aircrete into the form, giving it a jiggle to settle the mix into the corners.

Add Wire Mesh for Strength

Once it begins to thicken, I lay in a galvanized wire reinforcing grid. Pressing it down so it settles right in the center. Then I smooth the surface with a small trowel.