Make your own Lightweight Concrete Garden Boxes! This is PART 3.5, showing options to make your garden boxes from Perlite-based concrete. You can build these forms and precast your own 48″, 36″, or 24″ reinforced lightweight concrete panels that link together to make long lasting and durable concrete garden boxes.

Here is the weight of 3 cured panels made from regular concrete: . 48″ – 69lbs, 36″ – 50lbs, 24″ – 33lbs.

See the Youtube Video and download the Plans.

Background for the Cast Lightweight Concrete Garden Box Project – PART 3.5

Hi it’s Kent from MAN about TOOLS and this is a follow up video to Part 3 of my series of making garden box panels from lightweight concrete. These reinforced concrete panels link together to make long lasting rot proof garden boxes.

In part three I experimented with some concrete mixes looking for a good alternative to gravel-based concrete that was light and durable. In that part I looked at three blends. As that was more than enough to cover in one video. The vermiculite blend was my favourite but, I also wanted to try perlite as an aggregate.

So that’s the focus of this video. And to also add some colour to the concrete.

Perlite is a hard, highly porous material made by super-heating volcanic glass. Some viewers thought that perlite would be superior to vermiculite as perlite does not absorb as much water.

I’ll show the mixing, pouring, and unmolding, then look at the weight and durability results as compared to regular gravel-based concrete.

If you haven’t seen part 1 or part 2 of this series then you might get more from this video if you watch them first.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

I’ll be using the forms I built in part 2 of the series.

Lightweight Concrete Ingredients

This lightweight concrete blend is made from portland cement, perlite, and sand.

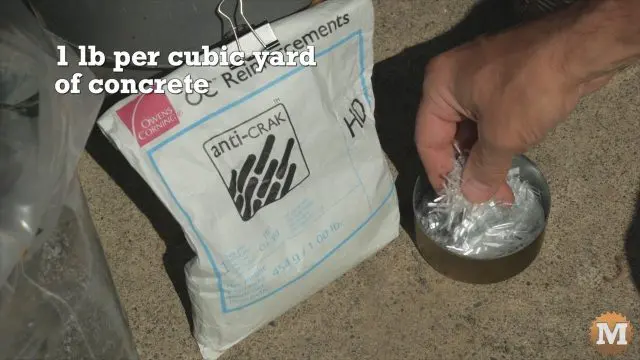

To some of the batches I’ll add a small amount of glass fibre for extra reinforcement.

You add about one pound of this fiber per cubic yard of concrete. So when I calculated how much I needed per batch it came down to a third of an ounce per 48 inch panel.

Lightweight Concrete Mix with Perlite- 1st Test

Here’s the proportions I used for the first attempt at perlite concrete: one part portland cement, two parts perlite, and one part sand. These proportions are by volume.

I didn’t realize how dusty the perlite would be so I was glad I was working outside. A mask would have been better. And I did wear one later on.

I add the perlite and sand to my wheelbarrow first. And add a little water to wet the mix.

Once it’s well blended, I add the Portland cement. And continue to add water a little at a time.

When I saw that the mix ratio was looking good and the wet perlite concrete blended smoothly, I added half as much more of the ingredients, in the same proportions, to increase the batch size so I’d have enough to fill my 48 inch form.

Filling the Form

I add a few shovel fulls to the form and push the perlite mix around the pipes with a small trowel.

I used a reciprocating saw, without the blade, to vibrate the form and settle the concrete mix. Then I laid in a section of reinforcing wire mesh.

Add Reinforcement to the Lightweight Concrete Panel

This galvanized wire mesh is cut from a large hog panel fence I bought from my local farm supply store. I used small bolt cutters to cut a piece of this heavy 4 gauge panel to fit the form.

Then I topped up the rest of this and vibrated it some more. I use a trowel to smooth the surface.

I liked the consistency of this first blend so, I decided to make another batch with the same proportions as the first. But this time I’d add some glass fibre for more reinforcement.

Perlite is very light and it’s easy to mix in a wheelbarrow. And for these tests I like this method as I can really see how it’s blending. And how much water I need without over doing it.

This second batch went well. Like the first, half fill the form, vibrate the mix to settle it and bring bubbles to the surface, add the wire grid, then top up, settle, and finish with a trowel. And I’ll round off the sides when it sets up.

It was the end of the day so I covered the forms with plastic and left them to harden.

The next morning I set up to make two more batches. This time in the 36 inch forms.

Cement Color

This third batch used the same proportions as the first two but, for this one I’ll add some red colour. I add two ounces to the mix in the wheelbarrow. And I’ll add some glass fibre again.

I start as before, blending the perlite and sand. I then dilute the red colour in water and add it to the wheelbarrow. And wow, it was very red!

Then I add some fibre. And finally the portland cement. There were a few chunks of portland so I broke them up by hand. Now it’s a matter of slowly adding water for just the right consistency.

Wire Mesh for Strength

You can see the sheen of the vegetable oil spray I use on the forms before filling them. Pam cooking spray works very well. I cover the wires that wrap around the pipes to keep the oil off them while spraying.

And like before, I filled the forms half away, settled it a bit with the reciprocating saw, add the mesh, and then top it up. And smooth any bubbles with a trowel.

The red colour looked to be pretty uniform throughout the mix. I think the key is to add it to water first. And to add it early in the blending.

I was getting a pretty good feeling that the perlite blend would be a good lightweight alternative, similar to the vermiculite blend from Part 3 of the series.

So, for the 4th form I decided to change things up with the proportions AND the type of cement.