CSA Aircrete Formula – 2nd Test Batch

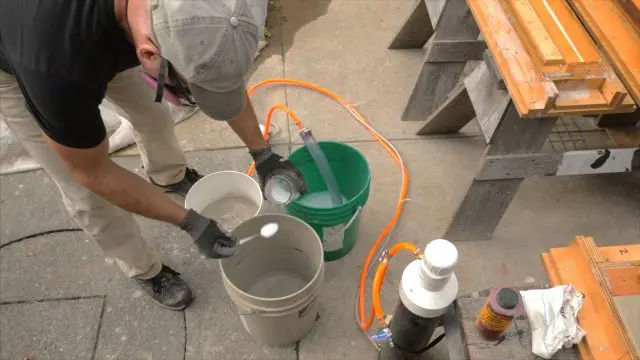

As before I start by dissolving the plasticizer in the water.

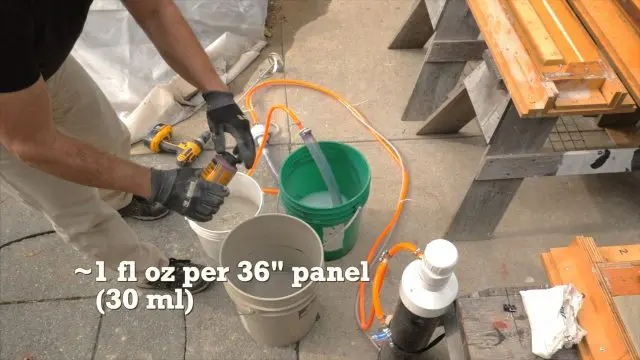

For this batch I’ll also add some liquid cement dye. About one fluid ounce.

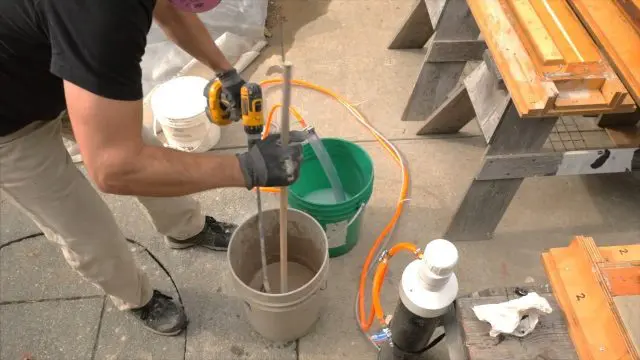

In this second batch I’ll use the same amount of water and Cement All as I did in the first.

As before, I slowly add the cement to the water. Then add the glass fiber. Hand stirring to free up any clumps from the sides or bottom of the pail. Then add the foam and blend it again with the mixer.

I think I got the foam right on this blend. Just enough to bring the mix up to the 8″ mark on my stir stick.

Fill Forms

Lay in Double Wire Grid

After the mix began to thicken I laid in a double wire grid. I make this grid from a section of galvanized fence. Folding it over to form a thin wire cage.