CSA Mortar Mix for Countertop Pour

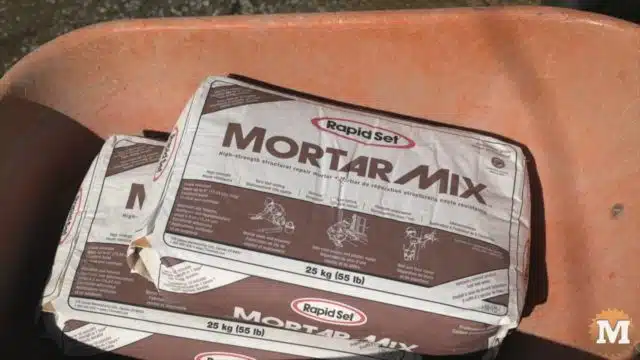

I’ll be using the same mortar mix that Michael Builds uses for his countertops.

I’ve used this mortar mix for my thin concrete garden boxes and the legs on my garden bench. The results are very good, it mixes and pours easily and settles well with very little troweling.

Ingredients for Countertop Pour

So to pour this potting bench countertop I’ll be using 3 bags of RapidSet brand CSA Mortar Mix, using a mixing attachment for my drill and I’ll be adding a plasticizer to make it pour like water. Along with a small amount of citric acid to extend the working time. And, I’ll add a small amount of glass fiber to increase the crack resistance.

Preparing the Concrete Form for Casting

It’s very important to level the form along it’s length and width and support it on a sturdy workbench or sawhorses.

Next I need to spray it with some type of oil to keep the concrete from sticking.

I’ve been using vegetable cooking spray in the past but I’ll be using some WD-40 penetrating oil on this pour. This is what Michael has been using so I wanted to see if there’s any difference.

Concrete Countertop Formula I used

Here’s the proportions for the mix: A 55 pound bag of CSA Mortar Mix (25kg), 5 quarts of water (4.7L), a bag of plasticizer 2.1oz (60g), and about 2 ounces of citric acid powder (50g).

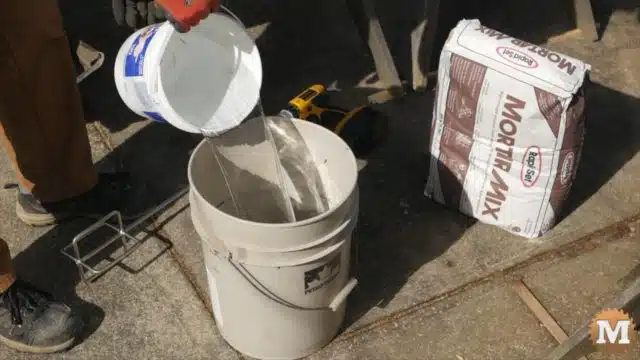

Mix the First Concrete Batch

I measure and add the water to a 5 gallon pail.

Then add the citric acid and plasticizer and dissolve it.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

Then I add about a third of a bag of the dry mortar mix at a time.

Blending it smooth with the mixing attachment on a drill. To the last bit of dry mix I then add a small amount of glass fibre. I am following the manufacturers recommendation for the amount of fibre here.

Hand Stir to Break up Clumps

Once I have it blended I give the bucket a good stir by hand to check for any clumps stuck to the side or bottom of the pail.

Pour Concrete into Countertop Form

When I think I have it thoroughly mixed I pour the wet concrete into the form.

Even though I’ve added the citric acid and used cold water to extend the working time, I get to the next batch right away. Planning is key here. I have to have everything ready to go for quick, consecutive batches.

Vibrate to Settle

I vibrate the form with a reciprocating saw to bring any bubbles to the surface.

Add a Wire Grid for Reinforcement

Once the mortar mix begins to thicken I lay in a wire grid for reinforcement.

This is a heavy gauge galvanized hog panel I bought at my livestock fencing supplier. I find small bolt cutters to work well for cutting the grid to size.

Oh NO!! RAIN!!

My nice sunny day changed unexpectedly and dark clouds with rain rolled in. I had to put together a quick improvised tent to keep the rain off the wet concrete.

Max came by to keep me company for a bit.

This is kind of funny as I will need to wet the concrete once it fully solidifies, warms to the touch, and developed a white haze. Turns out that began to happen just as the rain stopped and the sun came back out. Go figure huh?

The SUN is BACK!