Cover and Leave to Cure

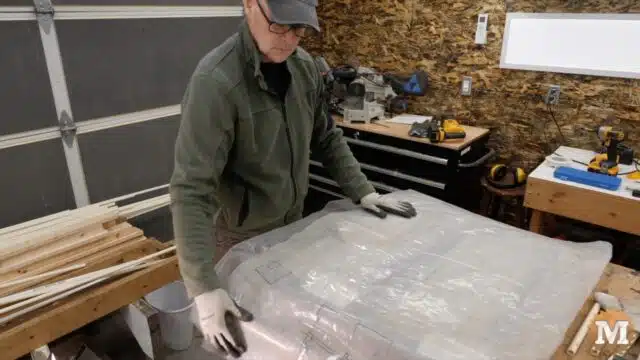

I set the new castings on a thick plastic sheet on the floor of my shop. I wrap the plastic up and over the top of the concrete panels like I was wrapping a present.

This will hold in the moisture so they don’t dry too quickly. After a few days (or up to a week) I then pull them back up on the bench or set them over sawhorses outside.

Dressing the Concrete Edges

The vacuum forms have a small radius at the top edge and this can leave a bump on the casting when filled right to the top.

After a week of curing this edge can be removed, or dressed, with a concrete rub brick. This will ensure your panels have no sharp edges.

This only takes a few minutes and it’s important to ensuring they fit together properly when assembling the garden box. I use the smooth side of the rub brick when working around the ends and holes in the casting. I want that inside corner to be sharp and free of any excess concrete.

Alternatively, you could use a small concrete or masonry brick for this.

Casting the 24″ Panels

The process is identical for the 24 inch panels.

Again I oil the cavity and pipes, slide them into place, mix some concrete and fill the molds half way, settle the concrete then top them up.

After 6 hours the pipes are extracted and the concrete is covered and left to harden further for a couple of days before dressing edges.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

And I think I slightly overfilled these 24″ forms. Under filling by an eighth of an inch would be ideal.

The only thing to note is that the 24 inch panels can take a bit longer to unmold. The shorter mold length reduces the natural flex of the plastic. So it can take a bit more patience to free the castings.

I really like the smooth finish you get from casting in these plastic molds. I have noticed a few more surface bubbles in some places though. I’m speculating that wood molds are porous so trapped air has somewhere to go where the plastic is a solid barrier to any air movement.