Leave to Cure for Two Days

I like to leave the concrete in the forms for 2 days at least. Longer if your temperatures are cooler.

Adding Additional Strength

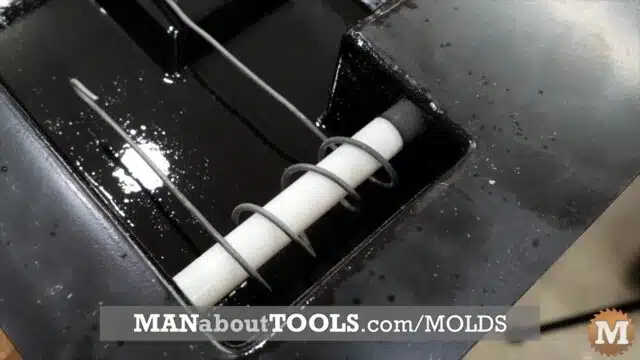

If you want to add more strength then you can embed some wire in the concrete in the form of a stiff wire grid down the middle. I use some concrete mesh sections that I cut with small bolt cutters. This mesh is 6″ x 6″ – 9 gauge (0.15″ diameter, 4mm)

I also add a spiralling wrap of galvanized fence wire around the pipes. This wire is 12 gauge (0.10″ diameter, 2.5mm)

You can wrap this wire around a section of larger diameter pipe, then I bend the ends for safety. I run the pipe through the center of this spiral when I’m prepping my molds.

These additional steps are optional. But, they are easy to do and not very costly. I have a blog post link here for all the details of any additional items or tools you might need.

For a few dollars more per bag you can buy high strength concrete mix.

High Strength Concrete

And with or without this additional wire and grid I think it’s a good idea to upgrade your concrete mix to a high strength blend. You end up with a stronger panel and a tough, smooth finish.

I rotate the wrap wire upwards while I fill the form half way. Then shake and vibrate it.

And this small trowel helps me get some concrete in behind the pipe where the wire wrap is.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

Then lay in the grid before topping up the form with more concrete.

Instead of the wire mesh you could use a section of galvanized hog panel or some pieces of rebar layed down the middle.

Unmold the Concrete Panels

So, the first concrete pour sat for two days.

Now we need to flip the molds upside down on your workspace.

It’s best to lift the mold from underneath and place the concrete against the edge of the bench. Then slowly and gently rotate it over.

You don’t want to stand the form on its thin edge or flange with 50 pounds of concrete in it.

Now gently lift the ends in an alternating fashion to free the casting from the mold.

Any excess oil on the concrete can be wiped away with a clean rag. I’ll set this first one aside for now.

When pulling upwards on an end, apply a little downward pressure with your other hand toward the middle of the form. The casting should come out clean.

The mold can then be wiped down with a clean cloth to remove any concrete dust or pieces and any leftover mineral oil.