Foamate Foam Generator

This works if you don’t have an air compressor and foam making system. I was fortunate that Darwin from the HoneyDo Carpenter sent me his large Foam Mate to try.

It worked so well right out of the box that I’d recommend it to anyone who wants to get into making aircrete.

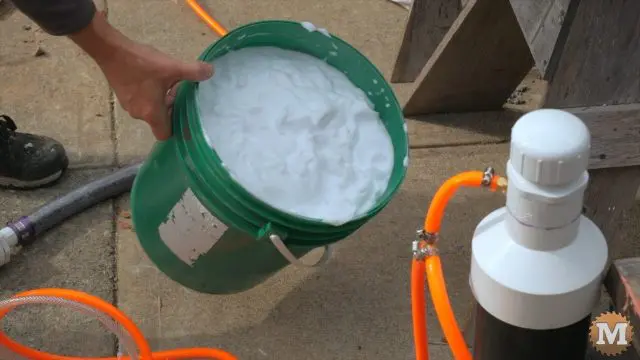

I simply poured the shampoo dilution into the tank, connected my air compressor hose and started making a dense shaving-cream-like foam instantly.

Aircrete Formula – 1st Test

I use a digital scale to weigh my gradients. This time around I use 15 pounds of portland cement, about 8 and a half pounds of water, 3/4 of a pound of foam and a pinch of fiber.

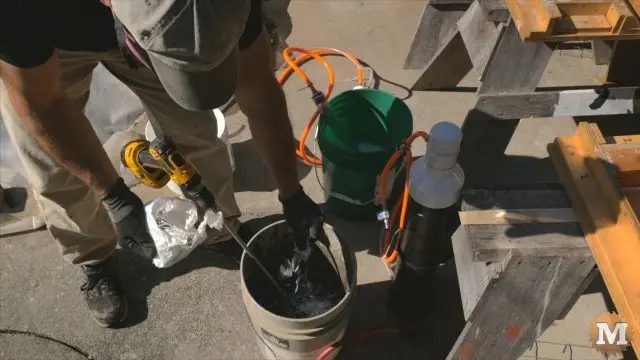

I slowly add the portland cement to the water while spinning the slurry with a paint mixing attachment on a drill. I want a smooth, well blended slurry here with no clumps or dry cement on the bottom or sides of the pail.

I’ll add the glass fibre and mix that in.

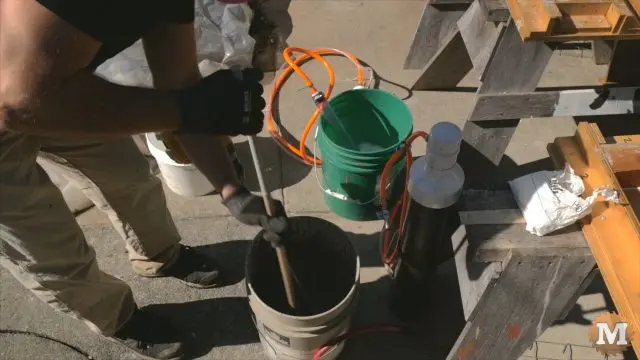

Then I stop and use an improvised stir stick from a wooden dowel to hand stir the cement mix. This helps free up any clumps.

With the slurry now ready, I connect the air hose to the foam mate and start making foam. Once its flowing thickly I add some to the slurry pail.

Pour Aircrete into Plywood Forms

I have a mark on my stir stick that approximates the amount of aircrete I need to fill one 36″ form. In this case, using a five gallon pail, I need the pail filled to the 8 inch mark as a minimum.

I’ll use my mixer to blend it all evenly. And hand-stir to make sure that everything was blending right to the bottom of the pail.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

Then I poured the aircrete into the form — giving it a bit of a jiggle to help settle it into the corners.

Lay in the Wire Grid

Once the aircrete begins to thicken, I gently lay in a galvanized wire reinforcing grid. Pressing it down so it settles right in the center. And smooth the surface with a trowel.