Make your own Concrete Raised Garden Beds! This is PART 2, showing a simpler method that uses standard framing lumber. You can build these forms and precast your own 48″, 36″, or 24″ reinforced concrete panels that lock together to make long lasting and durable concrete garden boxes. See the complete build video that shows step-by-step how to make the wooden molds for the precast garden boxes. An alternative to concrete garden edging.

Here is the weight of 3 panels that are cured: . 48″ – 69lbs, 36″ – 50lbs, 24″ – 33lbs.

See the Build Video and download the Plans.

How much concrete does it take to pour each size of panel?

Here’s the approximate square foot volume of each size of the 2.5” thick panels:

24” panel = 0.23 cu ft

36” panel = 0.36 cu ft

48” panel = 0.49 cu ft

Bags of ready mix concrete are sold in various sizes. Here is how much a bag of Quikrete will make:

40lb bag = 0.30 cu ft

50lb bag = 0.375 cu ft

60lb bag = 0.45 cu ft

80lb bag = 0.60 cu ft

Check the instructions on the bag to see how much it makes.

Background for the Cast Concrete Raised Garden Bed Project – PART 2

This is a follow-up to my blog post and video on casting your own concrete garden box panels. A year has passed so I think it’s time to see what improvements I can make.

There was a ton of interest in that video, so I wanted to shoot a sequel, AND find a faster, easier, and cheaper way to build the forms and cast the panels. These reinforced concrete panels link together to create long lasting, rot-proof garden boxes.

If you haven’t watched my first video then please have a look to see my original plywood form design.

I got a lot of comments and suggestions from the first video and I was overwhelmed by the positive reaction it received. So, thank you for your support and contribution!

I’ll address some of the most common comments and questions I received from that first video in the Q & A section below.

I first made these plywood forms and cast panels about 8 years ago, long before I planned a YouTube Channel. I was casting these for myself so at the time I wasn’t concerned that the forms be simple. I just wanted them to be reusable and for them to work.

I’m not a professional form builder, so I’m sure there’s other ways to cast these panels, but this is what works for me.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

Poured concrete raised garden beds

Many commented that the forms were too complicated to build. So I decided to go back and look at my original design to see if I could simplify and improve upon it. I still want to cast the concrete panels in the same size and shape so the new ones would connect and fit to the original ones.

My original plywood forms work very well so, if you’re already building yours that way then keep at it.

The NEW form design uses standard framing lumber instead of plywood. There’s fewer parts, and I’ve simplified the finishing. Instead of multiple coats of polyurethane, I’m using Food Grade Mineral oil to coat the forms. It’s cheaper, faster, and easier to apply. I like it as its non-toxic and won’t go rancid like vegetable oil.

You don’t need a lot of tools to make these forms and I’ll show some alternatives as I build them.

As before, I have a full set of plans available for download.

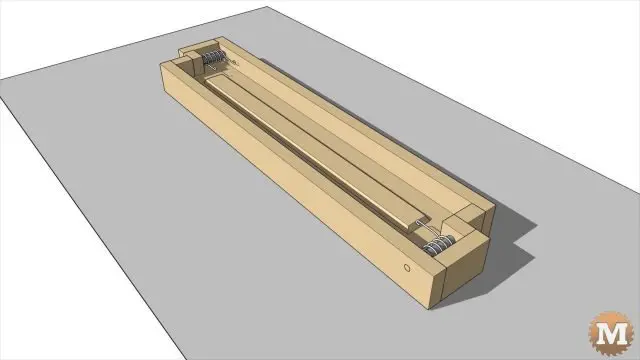

So here’s the new form design I came up with.

Precast concrete raised garden beds

These panels link together to create long lasting, rot proof concrete garden boxes.

DIY concrete raised beds.

I have plans available for download and I also have a list of all the tools I use for each project. So please check those out.

Concrete Garden Box Sides – the Build

The Parts

There’s three main parts to the form. The base, two identical ends, and two identical sides.

The base is made from a 2×10 with a beveled 1×4 as an inset, the ends and sides are made from a 2×6. The ends and sides have a peg made from wooden dowels to hold a pipe in place. The pipes are plastic electrical conduit with galvanized wire wrapped around them for reinforcement. When filled with concrete half way, a stiff wire mesh is laid in for additional strength.

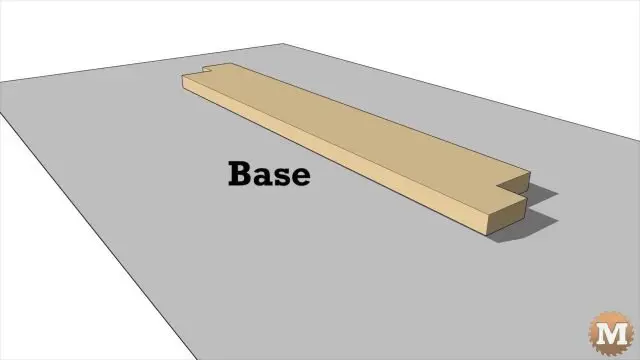

the BASE

I start by cutting a 2×10 to length, then ripping it to width on my table saw. This one will make a 48″ long panel. I cut these to length with a mitre saw.

But, a square and circular saw will work just as well.

To make the new forms the same inside dimensions as the previous plywood versions, I rip the 2×10 down to 8″ wide. I use my portable table saw for this.

A guide and a circular saw will also work.

I rip both edges on the table saw to give me a square corner on both sides. Framing lumber comes with a small rounded corner and I want to remove these.

I’m making three different lengths of forms this time. To cast a 48″, a 36″, and a 24″ panel. The drawings have dimensions for each. And I’ll show you some garden box variations you can assemble with these different sizes at the end of this build section.

After the base is ripped and trimmed to the final length, I’ll lay out the end cuts and inset location.

I’ll remove the corner pieces with a jigsaw. You could use a handsaw for these cuts instead.

I check the cut with a square.

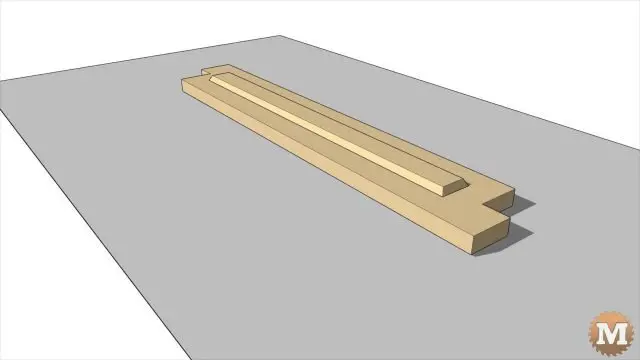

Make the INSET

The inset is an angled piece attached to the base mainly for decorative purposes. It’s not functionally required but I like the look. You could personalize your panels here by adding an oval, or circles, or a logo, or anything you want.

Just be sure that whatever you use has a bevelled edge so you can remove the panels from the base after casting. A 1×4 (which is actually 3/4 x 3 1/2) can be used to make this. I had some slightly thinner 5/8 inch boards so I used them. Either would work fine.

I rip these at 30 degrees on my table saw and cut to length on the miter saw.

I attach them with glue and screws from underneath. If you don’t use glue then you can change the inset design in future castings.

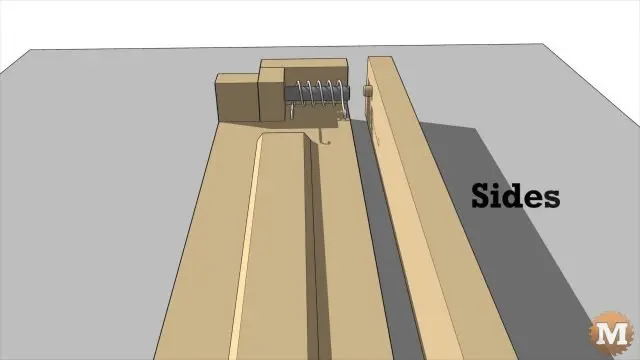

Make the SIDES

The sides are made from a 2×6. Like the base, they are cut to length on the miter saw.

Then ripped down to width on the table saw. (Depending on the tools you have you might decide to rip just the one side down, and that’s okay.)

After ripping I do the final trim to the exact length back on the miter saw.

The sides are laid out and the hole for the dowels drilled. I use a forstner bit for this but any 5/8″ drill bit would do.

I use a small bench top drill press but you could carefully freehand this or use a drill guide. You want the pipe holder pegs to be at right angles (or 90 degrees) to the sides.

I like to pre-drill the screw holes as well. It makes assembly a bit easier later on.