The BEAMS

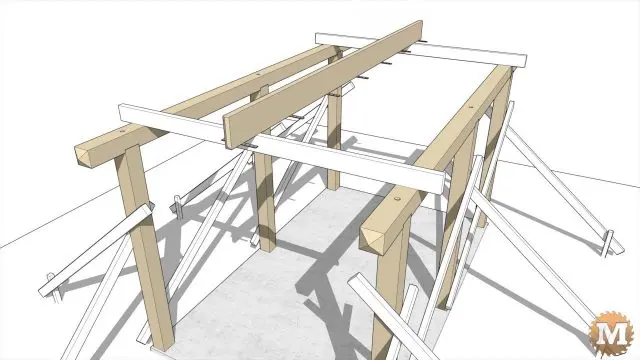

6×6 beams sit on the posts.

On each end they have a 30 degree bevel to form a point. Like the posts, I mark a line around each beam with a square.

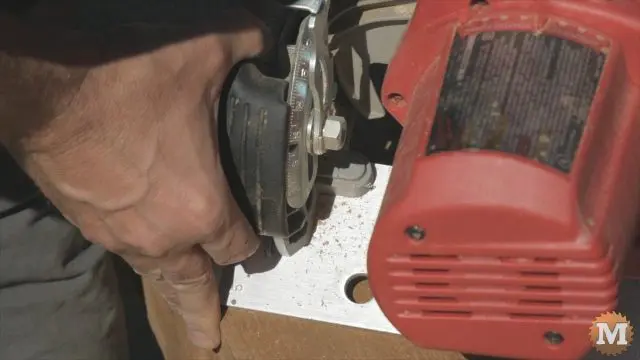

I set my circular saw at 30 degrees and make four cuts.

The plans include a cut list for the saw mill. Every part of this build was cut at Doug’s workshop ahead of assembly so we were pretty fussy with tolerances and lumber selection from the mill.

This could also be done with a large miter saw.

Chisel Work

If the beam is square then you are left with a nice point. I cleaned up the handsaw cuts with a chisel.

These beams sit down on the posts an inch. I cut this dado with a series of close saw cuts across the beam.

Then break off the pieces with a mallet. And finish up the groove with a chisel.

Each 6×6 beam has three of these dados. One for each post.

Drill Guide

The beam is flipped over and a counterbore and hole drilled for the lag bolt that will secure the beam to the top of each post.

(Disclaimer: As an Amazon Associate I earn from qualifying purchases. Thank you for helping to support my content this way. )

The ridge beam is 2″ x 9.5″. 30 degree angle cuts are made on each end of this beam. When complete, the beams are also chamfered with a power plane.

Temporary Bridge

The beams are lifted onto the posts and the lag bolts run in with a socket wrench.

A temporary bridge is set in place across the beams to hold the ridge beam in place at the proper height. The assembly was considered in the pergola design.

The rafter locations are marked on the underside of the ridge beam and galvanized strapping is screwed on. This strapping will make setting the rafters easier and will also add strength to the roof of the pergola and prevent sagging.

The Curved RAFTERS

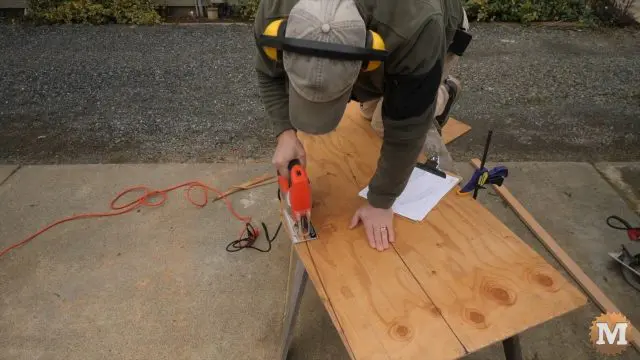

I start by making a pattern for the curved shape of the rafters.

The pattern will be cut from thin plywood. I lay out a grid with tape measure, pencil, and straight edge.

Then I mark points where the curve intersects the grid.

I tap in a nail at these points then bend a thin strip of metal across them to form the upper and lower curve of the rafter.

Drawing Curves

I used a strip of linoleum edge metal for this.

I trace the curve on the plywood with a sharpie.

On the plans I also show the radius values for the two curves that make up the shape of the rafter. The curves could also be struck with a long straight piece of trim like a compass.

Over sawhorses I rough off a piece of the pattern to make the next step easier.

Then cut the upper profile of the pattern with a jigsaw. Then use a belt sander to smooth and shape.

I reposition the pattern to cut the other curve.

The location of the beam is also marked on the pattern then this birds mouth is cut.

We had our sawyer mill boards just over 12″ wide for these rafters. Alternatively, thinner boards could be glued up to get the width required but, it’s a lot easier to just have them cut to what you need.

Completed Rafter Pattern